“The new play area looks great! Children on the park love it! We have had many comments from parents on how nice it is. Many thanks!”

⭐️⭐️⭐️⭐️⭐️

Tim Hill, Maes Glas Caravan Park

Product Details

Wetpour has been designed to minimise the risks of injury as a result of a fall from play equipment. It is an impact attenuating surface,… Full Details

This item is an ancillary product used to support our primary outdoor playground equipment range. As such we may not be able to provide a quotation where your project only requires safety surfacing, fencing or playground markings.

Contact Us

Disclaimer

Please note that, due to the introduction of sustainable materials within our products, photos and images of our products may differ slightly from those represented on our website and marketing material. Please contact us to discuss this further if you have any questions.

Description

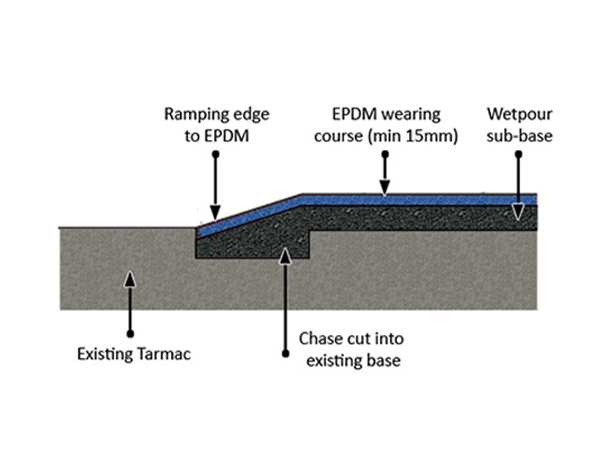

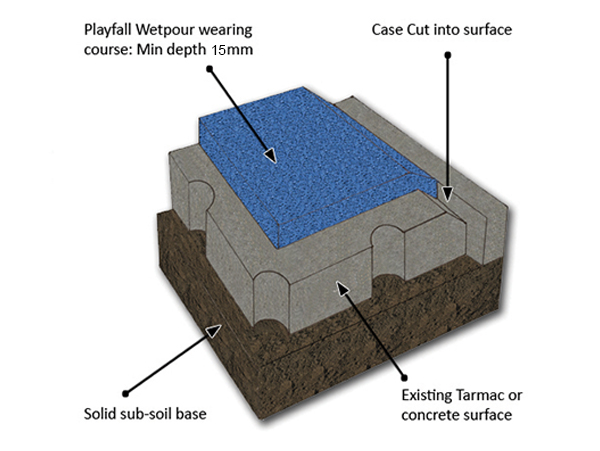

Wetpour has been designed to minimise the risks of injury as a result of a fall from play equipment. It is an impact attenuating surface, offering cushioning on impact, resistance to abrasion, slipping and ignition. Wetpour can be applied onto an existing tarmac or MOT sub-base, depending on required depth.

It is important to ensure that you find the wet pour safety surface that best fits your playground, so with this in mind we make sure to offer a flexible range of wet pour surfacing choices to our clients. The combination of stylish design and reliable safety support offered by this type of surfacing has made it a leading option for many playground settings.

This short guide will detail more on our range of wet pour safety surfacing and help you to make a fully informed decision on which option could suit you best. If you have any more questions on the specific nature of any of our wet pour surfacing options then you can get in touch with our team today, but for now, here are some of the key elements of this type of surfacing.

Description

Wetpour is a continuous surface laid in-situ. The product comprises of a base layer, 2-6mm Styrene-Butadiene-Rubber (SBR), essentially recycled truck tyres. This layer is laid at various depths depending on the Critical Fall Height (CFH) required. A wearing course of Ethylene Propylene Diene Monomer (EPDM rubber) is laid on top of the base course as required to a depth of 15 or 22mm.

Appearance

We have a large range of colours available (see colour chart), including 50/50 mix colours. The surface layer can include designs also. Almost any design is possible and can be used to enhance the play experience for children. Some examples of designs include fish, cats, roads, rivers and boats.

Creative Play can offer a design service if you are unsure about what would suit your project. Standard thicknesses of Wetpour are 20, 30, 40, 50, 60, 70, 80, 100, 140 (mm) and support CFH of up to 3.0 metres.

Colour Options

Performance

Wetpour is a totally weatherproof safety surface, and fully porous to allow effective drainage.

Maintenance

Wetpour safety surface should be kept clean of litter, leaves, etc. Pressure washing can remove debris and dirt with the quick draining surface remaining slip resistant. Solvents will remove paint and colouring and should not be used.

Repairs should be undertaken by Creative Play in the event that is is required. The surface comes with our five year warranty. Please note we cannot guarantee wetpour inlays into other manufacturers surfaces or overlays of existing surfaces.

Laying A New Sub-Base – Type 1 MOT

Where there is a requirement for a new sub-base to be installed prior to Wetpour being laid an engineered base as described below should be laid.

- Excavate the existing ground to the required depth – 150mm + depth of rubber to be laid.

- Lay 150mm compacted Type 1 MOT stone.

- A concrete kerb 150mm x 50mm should be used to contain the sub-base.

- These edges should be set above the compacted Type 1 MOT stone, as required by the depth of the rubber to be laid, to allow the rubber to finish flush with the top of the concrete edge.

The minimum depth of Wetpour surface which can be laid onto a Type 1 MOT sub-base is 40mm

Available in a stunning selection of classic tones and bright and vibrant colour options, our range of wet pour rubber surfacing provides the ideal style and safety complement to your new playground. Having designed and installed hundreds of playgrounds at different schools and parks over the past few years, Creative Play will be able to help you bring your dream playground design to life.

Finding your ideal wet pour play surface can be a big part of that, with different colours able to be combined to give you an exciting range of patterns and designs, or even additional games built into the surface of your playground area. Whatever colour scheme you choose for your playground equipment, it is a fantastic bonus to know that you have a wet pour rubber surfacing that will look the part and protect children as they play.

This type of surfacing is designed to safely absorb the kind of tumbles that come from children playing on playground equipment. Even with the most high-quality equipment, children will take a fall from time to time, so to know that your children are protected as they play is a fantastic feature.

Our team are happy to speak to you in more depth about all of the different wet pour rubber surfacing options we can offer to your playground to help you to find a playground that is both visually exciting and reliably safe. We’re available by phone or email, or you can even book a free playground consultation to have one of our experts come visit you and advise on the playground equipment and wet pour play surface you could make use of to provide a fantastic playground to the children at your school, nursery or park.

UV Discolouration

Please be aware that under certain environmental conditions i.e. warm sunny weather, Wetpour surfacing may be affected by UV discolouration during the laying process.

What is UV (Ultra Violet) Discolouration?

UV (Ultra Violet) Discoloration is the where the resin, when mixed with the topping granules reacts with the UV rays and takes on a yellow / brown tinge, which masks the true colour of the granulate beneath. This is most often seen in the summer where the surfaces are exposed to direct sunlight, the thin layer of binder which lies over the top of the granules can turn yellow causing the surfaces to appear discoloured.

This will be more noticeable on the following colours Light Blue, Dark Blue, Purple, Bright Orange, Orange, Pink, Bright Red, however all colours are susceptible to this to a greater or lesser extent.

This colour change affects only the resin used and not the rubber granule and as such the surface will return to its expected colour once this microscopic layer of resin has worn through. On large areas the surface may appear patchy due to variations in UV light during the laying process.